IntroductionThis was one of the projects that took me a long time to understand and plan. There are a lot of variables, and a lot of opinions on how it ought to be done. There's also ABYC codes providing input, and enough marketing information to make you insane. Let's begin by examining what I was starting with.

The original CS27 shore power system consists of a Hubbell 30A inlet fitting on the starboard cabin side. This inlet is then wired with 12G household solid core to a standard outlet in the galley. That outlet fed an automotive 6A trickle charger in the top of the starboard cockpit locker, and then went on to supply current to a few other outlets on the boat. There are a number of problems with this configuration, each of which I plan to address in this project.

At some point in the future I would really like to replace my inlet with a SmartPlug that incorporates a thermal breaker, and uses a more secure and watertight connection. Unfortunately, what I have works and the budget doesn't put a high priority on that upgrade quite yet. Maybe in a few years. Uncovering the Inlet

The AC inlet is not the least bit convenient to get to in a stock CS27. You need to remove trim, and the teak plywood panel on the aft cabin wall. Removing the trim isn't difficult if you are careful and patient. You will need a firm but small putty knife to start loosening the pieces near each nail hole, and then I switch to a small pry-bar to remove the pieces. When you get the wood off the back it will look like the photo to the right.

You can see the black AC wire coming in from the cabin side, then down toward the outlet. Unfortunately, just to check the connections you need to do this much dismantling. I'm hoping this won't need to happen often, but having gone through this much effort I plan to make sure I do it right.

Battery Charger

At this point my boat has two Interstate Group 27 deep cycle batteries. That means just about any charger is compatible. However, I don't want to rule out the possibility of selecting AGM or other types of batteries in the future. That means my charger needs to support multiple types of batteries.

The next criteria is the amperage capacity of the charger. I have a 30 amp inlet and shore power cord. That means the sum of the branch circuits cannot exceed 30A. My plan was to have a string of 15A outlets. Technically, that leaves 15A for a charger. In practical use, I don't plan to have AC in use on the boat. Since it's already there I'm keeping it, but I want 100% DC components. For that reason I dabbled with the idea of a more powerful charger. In the end I decided that sticking to a conservative plan would not only save me money, but make for a more reliable design. I decided my goal would be 15A charger.

Finally, I wanted a "mainstream" unit. I don't want an obscure charger. I want one that a lot of other people have on their boats. I want a charger that someone in a small port chandlery has heard of. Yes I realize there are brands out there that make great products for less money. I even researched one in particular that had much praise on Sailnet. But, integrating a lesser known charger into my boat isn't the plan I'm after as a novice to boat electrical systems. I need to be able to call in a pro if I get in over my head.

I spent much time in Sailing web sites looking at what other people had done, and which brands people had problems or high opinions of. The more I looked, the more I realized that for every person who likes one product, there is another who doesn't like it. I also think that people tend to post when they have a bad experience much more frequently than when they have a good one. So, I took my research with a grain of salt. I ended up selecting ProMariner's 1215i charger.

It can charge two battery banks independently, and it supports multiple battery types. It was also a model that I was finding on eBay every few weeks at a good price. When I finally received the package I set up a test in the basement with my batteries and some household wire. It was silent, and charged both batteries quickly. The previous owner had (significantly) over-filled the battery electrolite, so the first test run involved a lot of clean up. I used the hygrometer to suck out the extra fluid, and tried again. This time, it worked perfectly.

Installation is fairly simple. 14 AWG 120VAC input enters through the top and attaches with #10 ring terminals. The two bank outputs are then jumpered on the bottom as I only need to feed the ACR (which then feeds each bank as needed). Finally, a single positive and negative 14 AWG wire are run from the charger to the ship's main DC positive and negative busses. No rocket science involved at all.

AC Main PanelPanel SelectionAfter reading Don Casey's This Old Boat, I was planning to try to find an outdoor 30A main breaker box to save money. I thought I could find one with two branch circuits and save a lot of money compared to purchasing a marine panel. That plan didn't go so well. All I could find were huge boxes. The CS27 isn't a small boat, but there really aren't a lot of wide open surfaces to mount things in. I quickly realized this was a dead end, and the marine units would be the only thing compact enough to fit what little space I had left.

The first thing I discovered after digging into the marine panel suppliers is that most of them start with three branch circuits. Not too many panels have only two positions. What's the difference between a two position and a three position? Almost 2 inches. Doesn't sound like much until you are trying to find a space to squeeze this thing into. I found two products that I liked. First was the Blue Sea Sytems 360 Panel. The second was from BEP Marine. While I really like Blue Sea products, I ended up selecting BEP marine primarily because it cost a bit less due to me finding one on eBay. My decision came down to saving money, but the product I ended up with is very nice. It's quite solidly built, so I'm not in any way disappointed.

|

The CS27 Ravat Chronicles

In the fall of 2009 I began my journey as the owner of a twenty-seven foot 1977 Canadian Sailcraft sailboat. With only five lessons and a dream leading the way, I had become a boat owner. This blog captures my thoughts and experiences as a sailor determined to discover what lies over the horizon.

Friday, March 29, 2019

Shore Power Update

DC System Refit

Introduction

The DC system on Ravat is showing its age as well as its multiple layers of previous owner creativity. All of this leads to something between a fire hazard and entertainment. I am happy about neither. The DC system refit has the following primary goals:- Add a new main panel with a more appropriate number of breakers.

- Install appropriate size battery cables, and properly protect them.

- Replace lamp cord and non-marine wire with tinned and sealed marine cables.

- Add proper fuses to all devices.

- Remove all spaghetti and have all cables labeled when done.

- Have a good quality battery monitor.

Main Panel

The original CS panel, while visually pleasing, had extremely old wiring and uses spade connectors. It is also shy of the number of circuits I need to organize the loads on my boat. This means I need a new panel. After a lot of deliberation and measuring I decided that I will keep the main DC panel in the companion way.

Yes, the companion way is an inherently wet location, and is not really where electronics ought to be. One particularly clever alternative is turning the wet locker into an electronics locker. I like the aesthetics of that location as well as the dryness, however, I think I want to retain that wet locker for life jacket and foul weather gear storage. Tight as it is, it works in the tiny cabin.

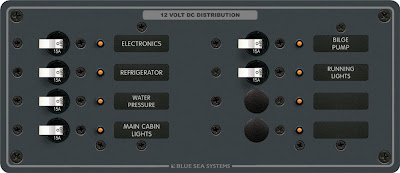

Having made that decision, I now needed to find a main panel which was horizontally oriented and had at least 8 breakers. My choice was made fairly simple when the horizontal criteria was considered. In the end I have selected the Blue Sea Systems #8385 8 position panel. It's almost a perfect fit for the existing space and gives me two additional breakers over the factory panel.

This will give me plenty of space to organize my circuits. I'll be consolidating quite a bit in the instruments and accessories cisruits using sub-panels which will free up what would otherwise be a lot of breakers.

Component Fusing

While I'm adding a number of additional breakers, I don't have unlimited space. With that in mind, I know I will need to consolidate components on circuits. To do this properly, I want to terminate each device in a block with a fuse. My first stop was Blue Sea Systems again, and my choice is the #5015 ST Fuse Block. I will be installing one of these for the instruments circuit, and another for the electronics circuit.

Blue Sea makes two functionally similar units. One uses the glass tube fuses, the other uses the ST automotive fuses. I like the idea of the bladed automotive fuses, although I'm not sure why. After some reasearch I was unable to determine any pros or cons beyond personal preference between the two styles. As a result, I went with the ST block.

The other decision I had to make here was whether or not I would purchase the model which has a ground terminal, or positive only. At the time I purchased all of the electrical components I had not fully laid out the locations where they would be mounted. As it's possible I may need to mount these blocks not necessarily in close proximity to the main ground bus, I thought it would be best for organization and intuitiveness if I was able to terminate each device's positive and negative wires in the same location.

My original plan was to have GenuineDealz.com make my cables to length and terminal size. Their prices for this sort of thing are fantastic and I would be assured a professional installation. When it came time to put together the schedule for wire lengths and terminals I quickly realized that the documentation additional effort on my part was just not worth it. There is a significant variety of post sizes on my busses and components, and to make the wires lay properly, I was going to need very specific lengths, not just "safe" rough estimates.

My original plan was to have GenuineDealz.com make my cables to length and terminal size. Their prices for this sort of thing are fantastic and I would be assured a professional installation. When it came time to put together the schedule for wire lengths and terminals I quickly realized that the documentation additional effort on my part was just not worth it. There is a significant variety of post sizes on my busses and components, and to make the wires lay properly, I was going to need very specific lengths, not just "safe" rough estimates.

Battery Cables

The existing battery cables were spindly little things that would no doubt explode in a fiery ball if allowed to stay on the boat. I was advised by many people to use at least a 2AWG cable to create the core DC pathways. While I certainly can't argue with that being a solid plan, I also couldn't quite justify the additional expense and hassle in routing the wires.

I created a comprehensive electrical plan for the boat. in it I diagrammed each wire's conservative length and amperage. There was simply no place anywhere on the boat which could require a 2AWG cable even using the 3% voltage drop tables. So, since I couldn't find a reason to spend the extra money, I went with 4AWG cables. I believe the highest load comes from my starter motor, and thus far the boat starts up immediately, and with much greater enthusiasm than the old 10AWG wire which used to feed that starter.

My original plan was to have GenuineDealz.com make my cables to length and terminal size. Their prices for this sort of thing are fantastic and I would be assured a professional installation. When it came time to put together the schedule for wire lengths and terminals I quickly realized that the documentation additional effort on my part was just not worth it. There is a significant variety of post sizes on my busses and components, and to make the wires lay properly, I was going to need very specific lengths, not just "safe" rough estimates.

My original plan was to have GenuineDealz.com make my cables to length and terminal size. Their prices for this sort of thing are fantastic and I would be assured a professional installation. When it came time to put together the schedule for wire lengths and terminals I quickly realized that the documentation additional effort on my part was just not worth it. There is a significant variety of post sizes on my busses and components, and to make the wires lay properly, I was going to need very specific lengths, not just "safe" rough estimates.

These realizations led me to purchase the FTZ crimper from GenuiineDealz.com. It's a lifetime tool to be certain. Built for industrial use, and works like a charm with the FTZ terminal assortment I also purchased. Having gone through this project now, I would say without hesitation that making my own cables was the right decision.

Automatic Charging Relay (ACR)

In order to properly maintain the batteries, and ACR will be installed to eliminate the need to switch the battery selector to "all". If a charging voltage is present, it will charge the batteries.

Adding a Cranking Battery

Electrical Projects

The electrical system of the boat is the infrastructure which delivers power to the electronic devices throughout. It is the batteries, the wires, and the magic that allows all the cool toys to light up and beep.

Shore Power Update

I believe that Ravat's shore power system was pretty standard, although anything but compliant with ABYC codes. The automotive battery charger was not well suited to marine battery charging, none of the wires were marine grade, and there was no overcurrent protection to be found. Some changes were in order.

DC System Refit The current wiring is a mix of lamp cord, spaghetti, and a complete lack of compliance with modern codes. It need to go and be replaced with marine grade wire, real crimped connections, proper fuses, bus bars, and a main DC panel with a reasonable number of fuses. Is that all? Ouch. Install Dedicated Cranking Battery The original configuration is two group 27 wet cells. I don't need AGM batteries, but I'd sure like a dedicated starter battery and a dedicated house bank. This project will add a dedicated start battery in some yet-to-be-determined location. |

Instrument Update

My boat came with a depth sounder and a knot log. I don't really have any problems with the older Standard Horizon instruments at all, so if the knot log worked, I wouldn't be touching them. Unfortunately, the speed log is dead. Call me a stickler, but I really don't like the look of mis-matched instruments, so off I go on another project.

The original transducers are installed with wood fairing blocks that I find to be less than elegant. The first problem is that the wood blocks weren't very well protected, and are in rough shape. The second thing I don't like is that there's no reason to have a paddlewheel perpendicular to the waterline. It can hug the hull just fine, and that eliminates the need for a protrusion from the hull.

My research has suggested a CS27 "ideal" practice of mounting the knot log paddle wheel under the floor in the V-birth area close to the bulkhead. The problem with doing so on my boat is that the teak and holley sole is screwed to the floor and the countersunk holes are bunged. There's no way to get in there for maintenance. I'm also not sure of the clearance available since the sole under that teak and holly is solid glass. For now, that location is out.

In the interest of getting the project done, my current preference is to keep the existing through-hull locations. The depth sounder will get a new fairing block cast in thickened epoxy. The speed log will simply parallel the hull. I will install the speed and depth instruments in exactly the same locations they originally occupied.

The choice of devices will be Raymarine ST60+. They seem to be the best value for the money. At this point I have removed the old fairing blocks and wiring and obtained the instruments. I'm waiting for the barrier coat before installing the fairing blocks and through-hulls.

In the interest of getting the project done, my current preference is to keep the existing through-hull locations. The depth sounder will get a new fairing block cast in thickened epoxy. The speed log will simply parallel the hull. I will install the speed and depth instruments in exactly the same locations they originally occupied.

The choice of devices will be Raymarine ST60+. They seem to be the best value for the money. At this point I have removed the old fairing blocks and wiring and obtained the instruments. I'm waiting for the barrier coat before installing the fairing blocks and through-hulls.

GPS Chart Plotter Update

Update? Well, sort of. I have a small and old hand held Magellan GPS which has graced the cockpit seats many times. Unfortunately, it chews through batteries like mad. It is also lacking a solid mount, although I suppose I could remedy that problem. I'd like to have something hard-wired into the boat's electrical system, with a solid mounting on the pedestal to make it convenient for the helmsman.

Although they are very sexy, the new large touch screen units are not what my old boat needs. They won't fit the pedestal very well. They are also too high tech. Yes, I said it. If I had a more modern boat I'd probably think about one, but it just throws the aesthetics for me. I'm looking for something small because I don't want it to be a visual anchor. I'd like it to mount in the ~ 8 inch area between the pedestal support tubes so that it can be viewed just above the binnacle compass.

Although they are very sexy, the new large touch screen units are not what my old boat needs. They won't fit the pedestal very well. They are also too high tech. Yes, I said it. If I had a more modern boat I'd probably think about one, but it just throws the aesthetics for me. I'm looking for something small because I don't want it to be a visual anchor. I'd like it to mount in the ~ 8 inch area between the pedestal support tubes so that it can be viewed just above the binnacle compass.

Although they are very sexy, the new large touch screen units are not what my old boat needs. They won't fit the pedestal very well. They are also too high tech. Yes, I said it. If I had a more modern boat I'd probably think about one, but it just throws the aesthetics for me. I'm looking for something small because I don't want it to be a visual anchor. I'd like it to mount in the ~ 8 inch area between the pedestal support tubes so that it can be viewed just above the binnacle compass.

Although they are very sexy, the new large touch screen units are not what my old boat needs. They won't fit the pedestal very well. They are also too high tech. Yes, I said it. If I had a more modern boat I'd probably think about one, but it just throws the aesthetics for me. I'm looking for something small because I don't want it to be a visual anchor. I'd like it to mount in the ~ 8 inch area between the pedestal support tubes so that it can be viewed just above the binnacle compass.

From a feature perspective I have no worries. The features I care about have been part of every GPS unit built in the last ten years. It needs to be able to output NMEA signals so that my VHF's DSC capability is enabled. I expect to be able to plot a series of waypoints, see my latitude and longitude, and speed over ground. A nice feature would be the ability to synchronize with a computer, but it's not essential. My preference is for an internal antenna, but I can work with external if need be.

Considering these requirements it became obvious that I was looking at low-end units, and I immediately found two which stood out: The $479 Standard Horizon CP180i, and the $449 Garmin GPSMap 431(Pre-loaded with US Inland Lakes - I'm on Lake Ontario). The next bump up in price brings me to a $699 Garmin 531 which adds screen resolution. It's hard to justify an extra $100 for screen resolution when my current hand held unit seems to be working fine, but it's worth keeping in the comparison just in case another feature jumps out.

Feature Comparison

| Standard Horizon CP180i | Garmin GPSMap 431 | Garmin GPSMap 531 | Garmin GPSMap 541 | |

| Adv. Price (defender.com) | $479 | $449 | $599 | $699 |

| Dimensions | 4.4"H x 7.1"W x 1.7"D | 5.0"H x 5.7"W x 2.7"D | 5.9"H x 6.4"W x 2.9"D | |

| Antenna | Internal | Internal (ext optional) | Internal (ext optional) | Internal (ext optional) |

| Screen Resolution | 320 x 240 | 240 x 320 | 234 x 320 | |

| Screen Dimension | 5" | 4" | ||

| Power Consumption | 520mA max @ 12v | 15W max @ 13.8v | 15W max @ 13.8v | 15W max @ 13.8v |

| Waterproof? | ??? | IPX7 | IPX7 | IPX7 |

| Cartography | C-MAP by Jeppeson NT+/MAX | Garmin | Garmin | Garmin |

Mounting Location

My intent is to mount the GPS on the pedestal immediately behind the binnacle compass. Since I'm looking down, I anticipate that the compass will not block the screen significantly. There are a number of options for raising the mount point a bit to mitigate this situation as well. When reading the installation instructions for each unit I discovered a unique requirement that Garmin lists: The unit needs to be mounted 20-38" away from a compass (distance depends on the model).

I did some Internet surfing and found that people don't seem to pay much attention to this requirement. People seem to mount the GPS on their pedestals all the time, and very few report any detectable issues. However, I wonder how many people have really measured deviation at all compass points? I tend to think the issue is minimal at best, however, knowing that Garmin says, "don't do it" puts a huge negative mark against the Garmin units. Based on this, I'm leaning heavily towards the Standard Horizon CP180i.

Subscribe to:

Posts (Atom)

For safety and protection from corrosion, this device is pretty important. I won't get into the details because they are covered thoroughly throughout the Internet and the suggested reading list on this site. After some research, and recommendations from other CS owners, I went with the

For safety and protection from corrosion, this device is pretty important. I won't get into the details because they are covered thoroughly throughout the Internet and the suggested reading list on this site. After some research, and recommendations from other CS owners, I went with the  Battery Monitor

Battery Monitor